Dynamic Vertical Farming: Energy Savings, Yield Optimization & Smart Climate Control

Introduction

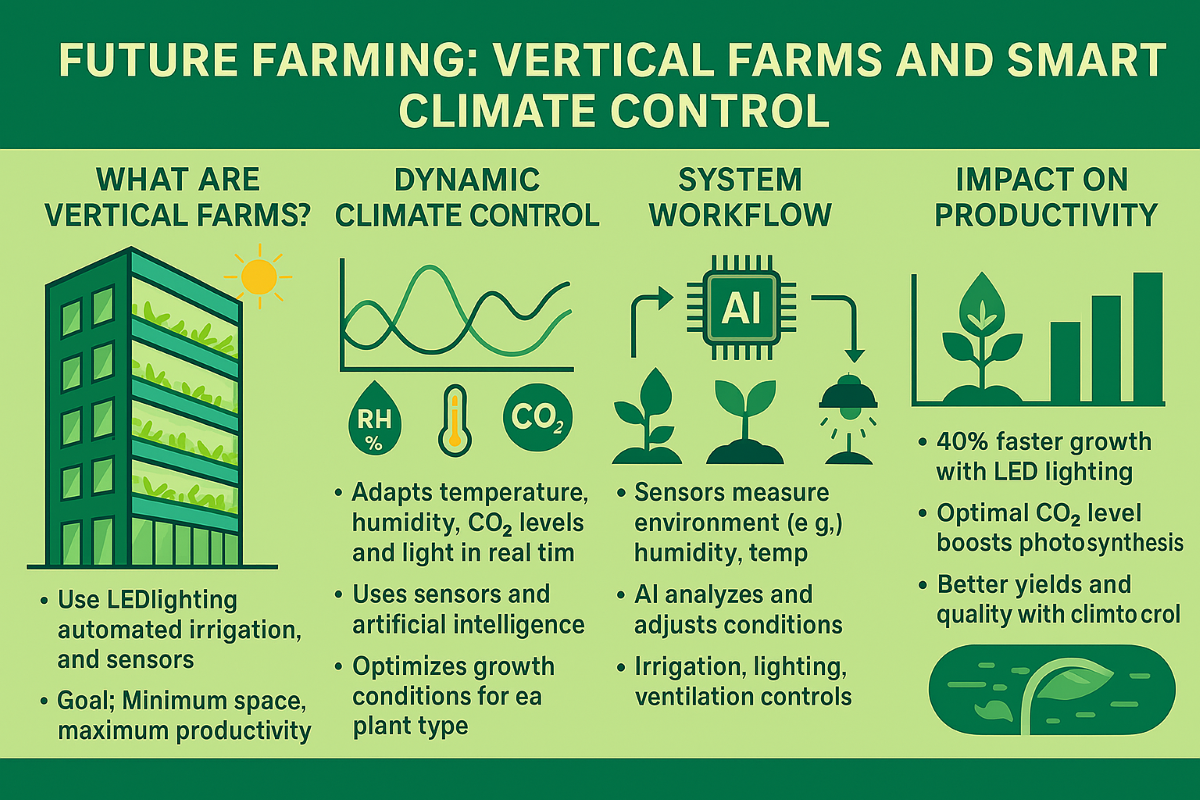

Vertical Farming Systems (VFS) are high-tech indoor farms, where crops are grown in stacked layers under fully controlled environments—usually with 100% artificial lighting.

The article “Vertical farming goes dynamic: optimizing resource use efficiency, product quality, and energy costs” examines how dynamic environmental control—adjusting parameters like light, temperature, humidity, and CO₂ on an hourly or sub-hourly basis—can:

-

Enhance resource efficiency (e.g., water, nutrients, electricity)

-

Improve yield and product quality (taste, nutrients)

-

Lower energy costs and increase cost-effectiveness

Unlike traditional VFS with constant conditions, dynamic systems align better with plant physiology and real-time energy prices. For example, adjusting light based on electricity costs (while maintaining the same daily light integral) resulted in up to 12% savings in lighting costs.

In 2022, Dutch electricity prices ranged from –222.36 €/MWh to +871 €/MWh—making smart energy use essential.

Key Objectives of Dynamic VFS

The article outlines five main objectives of using dynamic control in vertical farming:

1. Optimize Resource Efficiency

-

Reduce water use via targeted humidity, airflow, and EC control

-

Supply CO₂ only during peak photosynthetic periods

-

Use photothermal ratios to optimize carbohydrate storage in plants

2. Improve Product Quality

-

Increase antioxidants and vitamins, reduce disorders (e.g., tipburn)

-

Apply end-of-production (EOP) lighting to enhance shelf life and taste

-

Reduce nitrate content in spinach by ~60% using night lighting

3. Reduce Energy Costs

-

Shift lighting to off-peak hours

-

Apply optimization algorithms to cut electricity bills by 10–20%

4. Integrate Smart Sensors & Digital Twins

-

Use RGB, hyperspectral, thermal, and CO₂ sensors

-

Develop digital twins that automate environmental controls in real time

5. Enable Targeted Crop Breeding

-

Breed varieties adapted to dynamic climates (e.g., fast stomatal response)

-

Example: End-of-day far-red light increased tomato fruit partitioning by 10–20%

Challenges and Controversies

Despite promising results, several unresolved challenges remain:

-

EC Fluctuations: Help tomatoes but may harm leafy greens

-

Far-red Light: Good for tomatoes; increases fruit abortion in peppers

-

Yield vs. Energy Input: High-yield cereals require low-carbon electricity

-

Fluctuating Light: Leafy greens tolerate it; fruit crops may not

-

Night Lighting: Enhances quality but may disrupt circadian rhythms

-

Photoperiod Sensitivity: Some crops (e.g., cannabis) require strict lighting cycles

Physiological & Agronomic Effects

Photosynthesis & Transpiration

-

Syncing light and temperature boosts carbon gain by 10–40%

-

Pulsed lighting saves energy but may reduce photosynthesis in fruiting crops

-

Photothermal ratios improve growth phase alignment

Growth & Morphology

-

Dynamic light increases specific leaf area by 5–10%

-

Positive DIF (day > night temp) encourages elongation

-

Sudden EC/humidity changes impact plant expansion

Reproductive Development

-

Tomatoes benefit from far-red light; peppers do not

-

Short-day crops like cannabis need <14h light for flowering

Product Quality

-

Tipburn reduced with night EC/humidity control

-

Spinach nitrate reduced by 60% with night lighting

-

EOP lighting improves vitamin C and shelf life

Yield Response

-

Leafy greens maintain yields with fluctuating light if DLI ≈ 12.96 mol m⁻² d⁻¹

-

Tomato yield improves with spectral tuning

-

Pepper shows neutral to negative yield response

Strategic Outcomes

-

Energy Efficiency: 10–20% daily savings through smart lighting

-

Quality Enhancement: Improved taste, nutrients, and shelf life

-

Yield Stability: Dynamic systems sustain or increase yield

-

Digital Integration: Sensor networks + AI optimize performance

-

Breeding Innovation: New cultivars tailored for dynamic VFS

Investment & Cost Estimates

1. Infrastructure

-

Multi-tier systems: €2,000–€5,000/m²

2. Lighting

-

Dynamic LED systems: €400–€800/m² (10–20% more than static)

3. Sensor Systems

-

Thermal/hyperspectral cameras: €3,000–€30,000/unit

-

Sensor networks: 5–10% of CAPEX

4. Software & AI

-

Dynamic control software: 1–2% of annual budget

5. Labor

-

Initial training and data analysis: 5–10% of OPEX, declines over time

6. Breeding R&D

-

Long-term allocation: 2–5% of budget

7. Return on Investment

-

Expected ROI: 5–10 years, supported by premium pricing, energy savings, and reduced waste

References & Further Reading

-

Dynamic Vertical Farming Strategies:

Vertical farming goes dynamic (Frontiers in Science, 2024) -

Pulsed Lighting:

Pulsed LED-lighting as an energy saving technique (Olle & Viršile, 2021) -

Far-red Lighting in Tomato:

Adding far-red increases tomato yield (Kalaitzoglou et al., 2019) -

Sensor Technologies:

Plant disease detection by imaging sensors (Mahlein, 2016)

Conclusion: A Future-Ready Farming Paradigm

Dynamic environmental control is revolutionizing vertical farming. It merges:

-

Precision automation

-

Real-time energy management

-

Crop-specific breeding

-

Sensor-based decision-making

These systems enable sustainable food production in urban settings, creating resilient, cyber-physical ecosystems that can scale globally.

What is dynamic vertical farming?

Dynamic vertical farming is an advanced indoor agriculture technique in which environmental parameters—such as light intensity, spectrum, temperature, humidity, and CO₂ concentration—are adjusted dynamically, often on an hourly basis. This approach improves plant growth, resource efficiency, and energy savings by aligning environmental conditions with real-time plant needs and electricity market fluctuations.

How does dynamic lighting reduce energy costs in vertical farms?

Dynamic lighting systems use algorithms to adapt light intensity and scheduling based on electricity pricing and plant photosynthetic activity. By shifting most lighting to off-peak hours, growers can reduce daily energy costs by 10–20%, while maintaining the same Daily Light Integral (DLI) and overall crop productivity.

Why is far-red (FR) light used in vertical farming?

Far-red light enhances yield and dry matter partitioning in fruit crops like tomatoes, especially when used in short pulses at the end of the photoperiod. However, prolonged FR exposure can cause undesirable effects such as 20–25% fruit abortion in crops like sweet peppers and may reduce disease resistance in some species.

Can dynamic climate control improve crop quality?

Yes. Dynamic environmental control can significantly improve crop quality by reducing physiological disorders (e.g., tipburn, blossom-end rot), lowering nitrate levels (up to 60% reduction in spinach), enhancing antioxidant content (e.g., vitamin C and phenolics), and extending shelf life by 1–3 days.

What technologies are essential for dynamic vertical farming?

A fully functional dynamic vertical farming system typically includes:

-

Dimmable LED lighting with controllable spectra,

-

Environmental sensors (CO₂, temperature, humidity, EC),

-

Hyperspectral or thermal imaging systems,

-

AI-based automation and control software,

-

A digital twin model to simulate and optimize plant-environment interactions in real time.

The Frontiers in Science webinar on vertical farming brought together leading researchers, technologists, and policy experts to discuss the groundbreaking lead article: “Vertical Farming Goes Dynamic: Optimizing Resource Use Efficiency, Product Quality, and Energy Costs.”

This comprehensive session explored how dynamic environmental control, sensor-driven feedback systems, and strategic crop breeding can transform vertical farming from high-cost novelty into a profitable, sustainable food production model.

Key Concept: From Static to Dynamic Vertical Farming

Traditional vertical farms maintain constant environmental conditions. The lead article proposes a bold shift: use real-time data and dynamic control to adjust lighting, temperature, and CO2 levels in response to:

- Plant growth stage

- Daily and seasonal energy price fluctuations

- Target product quality (e.g. flavor, color, nutrients)

“Just because we can control everything, doesn’t mean we should keep it constant. Dynamic control is the real opportunity.” – Prof. Leo Marcelis

Environmental Benefits & System Efficiency

Vertical farms already offer significant advantages over traditional agriculture:

- Use of up to 95% less water

- No pesticide requirement due to sealed, hygienic environments

- Minimal land footprint – enabling urban food production

- Year-round, climate-independent harvests

However, energy consumption—especially for lighting—remains a major challenge. Dynamic control systems aim to:

- Reduce electricity costs (by up to 12%)

- Improve overall energy-use efficiency

- Optimize crop quality by adjusting parameters near harvest time

Intelligent Lighting: Key to Efficiency & Quality

Dynamic lighting adjusts intensity and spectrum throughout the day or growth cycle. Key findings include:

- Light can be lowered during high energy-price periods without biomass loss

- Increasing blue or red light near harvest enhances anthocyanins (color) and vitamin C

- Strategic lighting improves postharvest shelf life

Simulations using actual energy price data from the Netherlands showed how carbon gain could be maintained while cutting energy costs. By modifying the lighting pattern to match hourly price signals, growers could save money while maintaining yields.

Experimental Evidence: Fluctuating Light Works

Lead author Dr. Elias Kaiser presented a multi-species experiment comparing constant vs. dynamic light:

- Tested 4 leafy vegetables under 3 light patterns

- All treatments received the same total light (DLI)

- No significant reduction in fresh weight under dynamic light

- Specific Leaf Area (SLA) increased in 2 crops — thinner, possibly more efficient leaves

These results are consistent with previous studies and point to a broader physiological trend: crops can thrive under fluctuating lighting if baseline intensity is maintained.

Model-Driven Crop Control & Feedback Loops

Dr. Silvere Shabaan introduced a model that predicts daily photosynthesis and energy cost based on:

- Dynamic light intensity patterns

- Plant’s photosynthetic capacity, circadian rhythm, and stomatal conductance

- Energy prices (updated every 15–60 minutes)

This system sets daily light strategies that balance:

- Cost savings (12%+)

- Carbon gain consistency

- Potential transpiration reductions (less dehumidification required)

The next frontier: integrating real-time sensor data to adapt models dynamically and account for plant acclimation over time.

Promising Sensing Technologies

Panelists discussed the most promising tools for real-time crop feedback:

- Chlorophyll fluorescence imaging – measures photosynthetic performance

- Thermal imaging – tracks transpiration and stomatal behavior

- Plant wearables – next-gen sensors that track leaf-level metrics cheaply

These technologies work at the time scale of minutes, making them well-suited for responsive environmental control.

Continuous Integration: Breeding Meets Environment

A major theme of the discussion: crop genetics must align with controlled environments. Traits for vertical farming include:

- Compact, high-density growth

- Short life cycles

- High harvest index (more edible biomass)

- Tailored nutritional and sensory profiles

The feedback loop looks like this:

- Choose or breed a crop with desirable traits

- Monitor and model crop behavior under dynamic control

- Adjust environmental parameters to optimize growth

- Feed results back into the next breeding cycle

Policy, Scalability & Global Potential

Key enablers for real-world impact:

- Government recognition & regulatory frameworks

- Public-private R&D funding for breeding, tech integration, and training

- Support for low-cost systems in developing regions

- Interdisciplinary collaboration between scientists, engineers, and growers

“We have to prove the model works—not just in labs, but in commercial farms.” – Christine Zimmermann-Loessl, AVF Chair

Final Messages from the Panel

- Kevin Folta: Environment and genetics are a partnership. Let’s find the right plants for the right conditions.

- Christine Zimmermann-Loessl: Science is inspiring, but we must translate it into real farms that feed people.

- Leo Marcelis: The best control is dynamic control, and integration is key.